Vacheron Constantin and the Geneva Seal

In the world of watches and especially the world of Haute Horlogerie, there are several quality signs. The COSC chronometer test the most well known and many timepieces from many brands are certified by the Official Swiss Chronometer Testing Institute. Another proof of quality, one that goes much further than ‘just’ the timepiece’s accuracy, is the Hallmark of Geneva or also referred to as Geneva Seal. As of June 2013 all Vacheron Constantin timepieces bearing this seal of quality will comply with the newest standards. In two videos Vacheron Constantin explains the Geneva Seal’s history and the impact on the production of watches of this Genevan brand.

The Geneva Seal was set up on November 6, 1886. This was done on request of the Société des Horloger, who saw the international reputation of Genevan watches being compromised by both Swiss and foreign counterfeiters. The main task was to protect the reputation of the name “Geneva” which was inscribed on the movements.

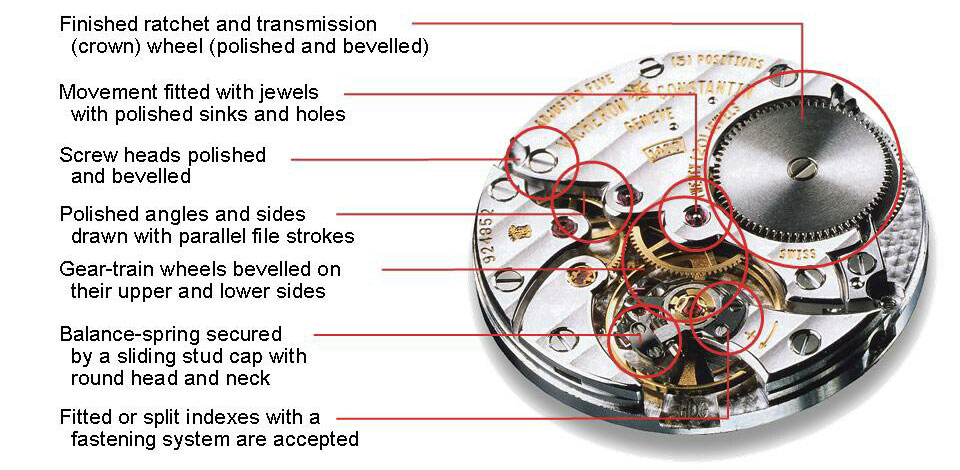

While the requirements have been rather rigorous, they mainly focused on aspects of the finishing and polishing of movement components. These criteria were by no means simple criteria, as they dictated extensive polishing, finishing and decorating the movement, also in places not visible to the watch’s owner and only to be admired by a watchmaker when a watch is being serviced.

Of the 20 million watches produced in Switzerland each year, only 24,000 bear the Hallmark of Geneva. All parts of the movement, from the mainplate to the smallest screw, are hand-finished according to traditional techniques including polished chamfers, straight-grained sides, smoothed down or levelled faces, polished or circular-grained screw heads with chamfered edges. Yes even the finishing of the screw heads must comply with the Geneva Seal requirements.

Still new, stricter, requirements were necessary. The new requirements, introduced in 2012, now have been extended to include the components that link the movement to the case and dial, and the performance of the watch on the wrist of its wearer (this will be mimicked by a machine). With the new requirements it is the entire timepiece that bears the Hallmark of Geneva!

Did you know that with 70 per cent of Vacheron Constantin’s production carries the Geneva Hallmark?

Vacheron Constantin have dedicated a special micro-site to the Geneva Hallmark (or Geneva Seal) and explain everything about the history, the requirements and even show all parts that have to be finished. Click here for the Hallmark of Geneva micro-site.

In the following two videos Julien Marchenoir (among others) also explain the impact of the Geneva Hallmark on Vacheron Constantin’s production and production facilities. Below the videos we listed all twelve historic requirements and the four new requirements.

The twelve historic requirements

- The quality of all parts and components of the movement, including those used for auxiliary mechanisms, must comply with the standards prescribed by the Office for the optional inspection of Genevan watches. Steel parts must display polished angles and their sides parallel file strokes, their visible faces must be smoothed and polished, screw heads must be polished or circular grained and their rim and slot bevelled.

- All movements must be fitted on the going train and the escapement with ruby jewels with polished hole. On the bridge side, jewels must be semi-mirror polished and their sinks polished. A centre-wheel jewel in the mainplate is not required.

- The balance spring must be secured by a sliding stud cap with round head and neck. Mobile studholders are accepted.

- Fitted or split indexes (regulators) with a fastening system are accepted, save on extra-thin movements where the system is not mandatory.

- Regulating systems featuring a balance wheel with variable radius of rotation are accepted provided they comply with certain conditions.

- Geartrain wheels must be bevelled on their upper and lower sides and their sinks polished. For wheels 0.15 mm thick or less, bevelling on the bridge side only is tolerated.

- Pinion shanks and faces must be polished.

- A lightweight escape wheel is mandatory: no more than 0.16 mm thick for larger sizes or 0.13 mm for wheels less than 18 mm across; locking faces must be polished.

- The lever’s angle of travel must be contained by solid bankings, to the exclusion of pins or studs.

- Movements fitted with shock absorbers are accepted.

- The ratchet and transmission (crown) wheel must be finished in conformity with prescribed models.

- Wire springs are prohibited.

The additional requirements introduced in 2012:

- Testing of the accuracy of the watch over a continuous seven-day period. Manually wound and self-winding watches are tested on a machine simulating the movement of the wearer.

- Testing of its water resistance. Hermetic value tested in the atmosphere and water-resistant watch must comply with the manufacturers’ claims.

- Testing of the power reserve to ensure that it meets or exceeds the claim of the watchmaker.

- Testing of its functions. All the functions of the watch are tested over one cycle.