A Technical Perspective – A guide to the Certifications and Quality Seals

COSC, Geneva Seal, Fleurier Quality Foundation, ISO standards… Watchmakers endorse their products with various certification marks to demonstrate their commitment to quality. These certifications address to multiple aspects of quality, relating to criteria as different as precision, durability, robustness, aesthetic or even provenance. This installment of A Technical Perspective provides a guide to quality and chronometric certifications seals.

A bit of history

Very early, and well-before marketing or advertising were theorized, watchmakers worked on building a reputation of quality around their products and their name. The concept of chronometry really developed during the 18th century, when long-haul travellers needed sharp timekeepers to enable them to determine their position at sea reliably. Manufacturing precise watches became a subject of competition between watchmakers, specifically at observatories, which were founded as guardians of accurate time. There was fierce rivalry at observatory contests and, together with the awards at international exhibitions, the prizes obtained at Geneva, Neuchatel, Besançon or Kew were often used for publicity purposes.

The observatory competitions ended in the early 1970s, with the advent of quartz watches. The COSC (Contrôle Officiel Suisse des Chronomètres) was created in 1973, encompassing the former independent Swiss laboratories and observatories, and defining the criteria to meet for a movement to be granted with a chronometer certificate.

From a different perspective, among the earliest certifications, the famed Geneva Seal was created in 1886, defining high quality standards for the manufacturing of watches, mostly with the finishing and decoration of the movement, together with some specifications on technical design. But most of all, it was aimed at protecting Geneva manufacturers, as this certification is reserved for watches made in the Canton of Geneva.

How do you define quality?

Over the years, watchmakers debated the need for a definition of quality – and of course, there is no single answer. This has led to the creation of different certifications, addressing different aspects of quality. Among the various criteria evaluated, some are related to the watch design while others are directly connected to the performances of each piece produced. Quality starts with a good design, from the beginning of product development, and shall be then deployed throughout the whole production process and the whole firm.

Different norms are used for design control, applying to product development processes. These can be referring to technical or aesthetical aspects of the watch or its components. For instance, movements must be finely finished and decorated to obtain the Geneva Seal or the Fleurier Quality Foundation. Prototypes are submitted and tested to approve the overall design and quality of a product. Beyond internal requirements, the widely used Chronofiable certification focuses on durability and reliability of watches, simulating several months of wear. Such testing procedures damage watches, they cannot be carried out on the whole production.

Chronofiable tests are carried out by Laboratoire Dubois. Ageing cycles involve indirect shocks as well as temperature and humidity variations.

After the development phase, quality management systems aim at ensuring that the compliance with each brand’s requirements. Numerous quality aspects are tested and eventually certified for each single watch produced. These include in particular, accuracy, water resistance, power reserve and functions of the watches.

COSC and other chronometric certifications

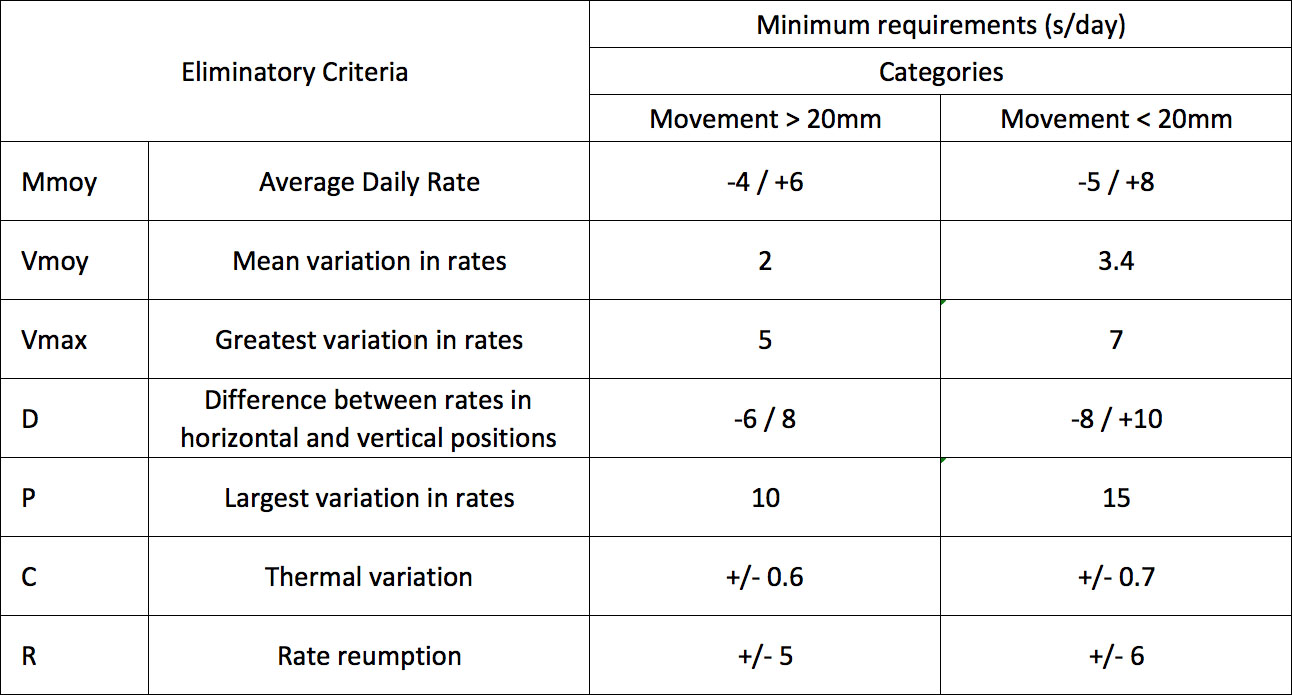

COSC is the best-known watch certifying organization, with well over 1 million units examined every year (knowing that the entire Rolex production and almost all the Omega watches go through the process… That’s already over 1.5 millions watches examined, with these two brands only). The COSC is testing the accuracy of non-cased movements, delivering a chronometer certificate belonging uniquely to the movement tested. The procedure lasts 16 days, tolerating the following deviations for mechanical movements.

Table summing up the COSC degrees of tolerance. Movements are tested in 5 positions and at different temperatures. Only the movement meeting the precision criteria established under the norm ISO3159 are granted an official chronometer certificate.

The COSC therefore certifies that a movement (and not a watch) operated within a defined accuracy range at a given time of his life. What happens afterwards, in particular when the movement is cased, is not guaranteed.

An example of COSC Certificate

Other chronometric certificates test cased movements, as the operations carried out after the movements are tested at COSC may alter their performances. This is the case for the Besançon or Glasshütte Observatories certificates.

COSC chronometric tolerances shall be seen as an industry standard. Even if they are not always officially certified, trusted and widely used movements like the ETA2892 or ETA7750 can easily be regulated to COSC level. This is a reason why high-end Haute Horlogerie brands rarely use the COSC certification, potentially shared with brands at a way-lower price point. Incidentally, some brands such as Seiko, Richard Mille or Ulysse Nardin have created their own chronometric certificates – stricter than COSC – on some of their watches.

Geneva Seal (Poinçon de Genève)

The Hallmark of Geneva (poinçon de Genève) certifies compliance with the traditions of Genevan workmanship. Its office is today part of TIMELAB – the Geneva Laboratory of Horology and Microengineering. To be awarded the certification, the candidate company has to be registered in the Canton of Geneva, where must also have been carried out the assembly, adjustment and casing-up of the movement and any additional mechanical modules, as well as the inspection of the cased-up watch.

Strict manufacturing and finishing specifications apply to each component, to guarantee high-grade finishes and long-time reliability. The movement, additional modules and the exterior parts of the watch have to be approved by a technical committee. In 2012, the Geneva Seal evolved significantly, with notable additions. In particular, all the cased-up watches have to comply with defined criteria. These new requirements include testing the water-resistance, the rate, the functions and the power-reserve of the watch.

This changes came a few years after Patek Philippe announced it would be establishing its own quality mark, incorporating the best of the Geneva Seal adding criteria quite similar to those added by the 2012 update.

A Vacheron Constantin watch bearing the Geneva Seal. Among watchmakers who regularly submit watches to the Geneva seal certification are also Cartier, Chopard, Roger Dubuis and Ateliers de Monaco.

Fleurier Quality Foundation (FQF)

The Fleurier Quality certification was created in 2001 by Chopard, Parmigiani and Bovet, later joined by Vaucher Manufacture (an external manufacture working for several brands). Its interest lies in the fact that it encompasses comprehensive criteria and stages of testing, to guarantee at the same time a technical conception, a high-quality finishing and a control of the precision and robustness of each watch. The Qualité Fleurier tests were actually the most holistic tests back in 2001 and have inspired other quality tests and certifications, which have now risen to similar levels of rigourousness.

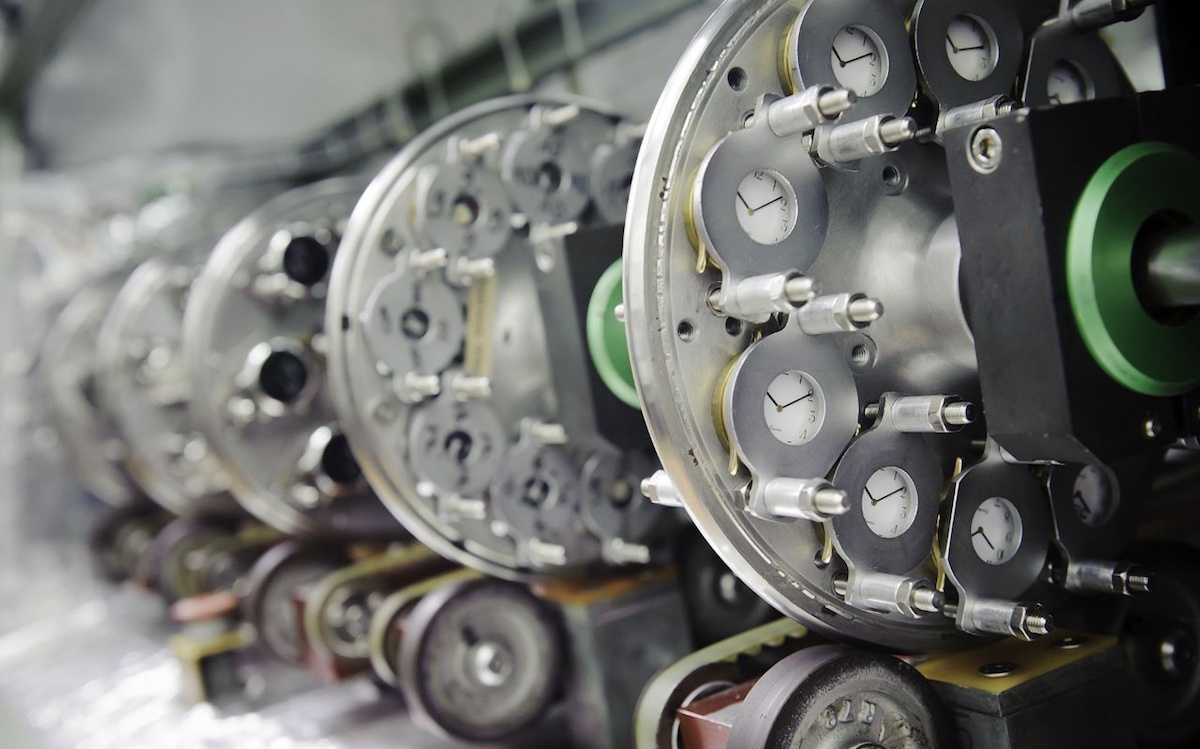

Fleuritest at the independent Fleurier Quality Foundation simulating the movements of a wearer during 24 hours.

To receive the Fleurier Quality certification a watch must be manufactured 100% in Switzerland. For the product development phase, the quality of its finishes are validated by the Fleurier Quality Foundation while its technical conception is tested with a Chronofiable test. On the manufacturing side, every movement and every watch must successfully pass the COSC and Fleuritest trials.

A L.U.C Chopard Watch, with Qualité Fleurier certification

METAS & Master Chronometer

In 2014, Omega worked with the Swiss Federal Institute for Metrology (METAS) to establish a new, independent certification for mechanical watches further the introduction of the Master Chronometer. To earn the name Master Chronometer, the finished watch, whose movement is a COSC chronometer, passes tests that replicate real-life wearing conditions and demonstrate resistance to water and magnetic fields. In particular, the function of each movement and each watch is tested for magnetic fields greater than 15’000 Gauss. The average daily precision must be between 0 and +5 seconds a day before and after the exposure to magnetic fields.

Brand certifications

To underline their quality standards while standing out from the crowd, several brands have developed their own certification. While it is difficult to name all existing labels, we are presenting here a few of them.

The Patek Philippe Seal (read our article about it here) was created in 2009. The brand wanted to define its own standards of excellence. While Patek Philippe had been one of the biggest user and promoter of the Geneva Seal for years, the brand probably felt it was lacking some performance requirements. Newcomers to the ‘Poinçon de Genève’ might also have been a motivation to step out. Last, Patek Philippe’s new production facilities outside Geneva were incompatible with the restriction on the provenance. While incorporating the best of the Geneva Seal such as standards of finish, the Patek Philippe Seal encompasses the whole watch and not just its movement (something that the Geneva Seal now also incorporates.) It also includes several performance tests such as rate accuracy.

The Patek Philippe Seal engraved on a movement.

Created in 2004, the Jaeger-Lecoultre 1000 hours involves a battery of test lasting nearly 6 weeks. Timekeeping accuracy is tested in different positions, at different temperatures. The power reserve and the water resistance of the watch are tested. Among other trials, a machine simulates daily wear and makes sure that all parts are securely fixed. In a similar fashion, Montblanc has implemented a 500-hours quality certificate on part of its production.

‘Quality is not an act, it is a habit’ – Aristotle

Naturally, quality certification involves a marketing dimension. But submitting its production to 1000 hours of control or to the standards of the FQF or Geneva Seal is not an easy path. And quality management pays off. Certification maintains the environment to ensure compliance with requirements. It evidences that a brand follows a formalized, consistent quality management system.

The Superlative Chronometer green seal accompanying every Rolex watch attest it has successfully undergone a series of controls by Rolex according to its own criteria (water resistance, power reserve, etc.) in addition to the official COSC certification of its movement. Beyond the wax seal, their deep, long-lasting commitment to quality has made Rolex a benchmark for reliability, allowing the brand to now offer an industry leading 5-year warranty on all models. Quality management does pay off.

3 responses

top work. thank you.

I suppose one could also add a most infamous certification:

High temperature: 48 hours at 160 °F (71 °C) followed by 30 minutes at 200 °F (93 °C)

Low temperature: Four hours at 0 °F (?18 °C)

Temperature cycling in near-vacuum: Fifteen cycles of heating to 160 °F (71 °C) for 45 minutes, followed by cooling to 0 °F (?18 °C) for 45 minutes at 10?6 atm

Humidity: 250 hours at temperatures between 68 °F (20 °C) and 160 °F (71 °C) at relative humidity of 95%

Oxygen environment: 100% oxygen at 0.35 atm and 71 °C for 48 hours

Shock: Six 11ms 40 g shocks from different directions

Linear acceleration: from 1 to 7.25 g within 333 seconds

Low pressure: 90 minutes at 10?6 atm at 160 °F (71 °C) followed by 30 minutes at 200 °F (93 °C)

High pressure: 1.6 atm for one hour

Vibration: three cycles of 30 minutes vibration varying from 5 to 2000 Hz with minimum 8.8 g impulse

Acoustic noise: 30 minutes at 130 dB from 40 to 10,000 Hz[6][14]

[via Wikipedia]

Current cast of NASA flight test survivors includes the humble Casio DW5600C and Timex Ironman, and of course Omega’s Speedmaster/3570.50 and X-33. It still warms my heart to know the Speedy is the only watch, mechanical or otherwise, approved for EVA. So cheers to the Swiss!

Still, other Swiss champions including mighty Rolex couldn’t cut it back then. With all of these new performance standards it would be fascinating to find out just how well they would manage now.

Thanks, Monochrome!

Cheers,

db

*edit* and Seiko’s A829.