Interview with the inventor of the Constant Escapement, Nicolas Déhon

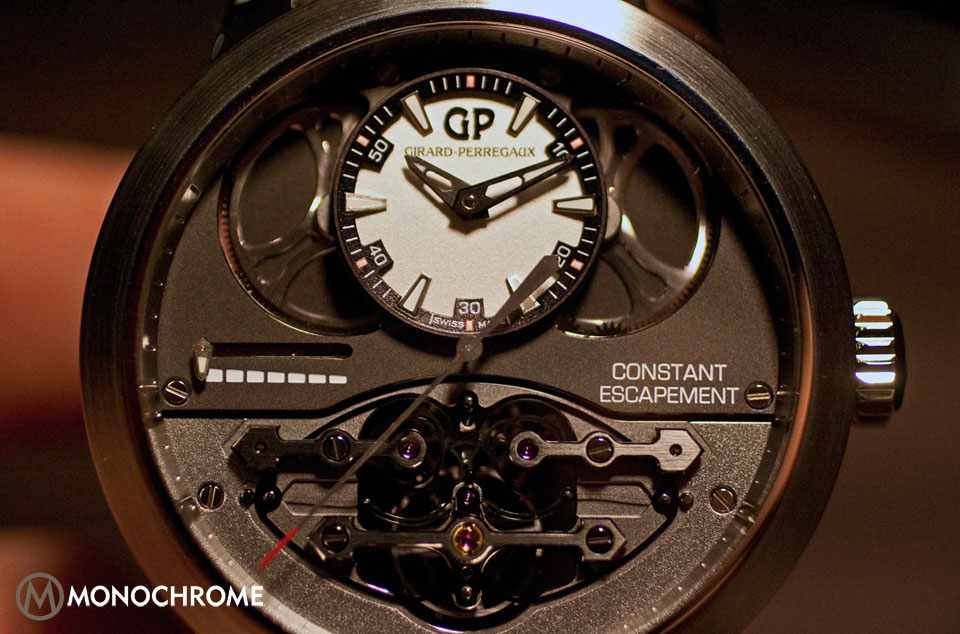

Prior to Basel, we broke the story about Girard-Perregaux’s Constant Escapement Watch (see here) for Baselworld 2013 and explained its technological workings. We also introduced Nicolas Déhon, the inventor of the constant escapement. During Basel, Mr. Déhon was kind enough to speak with us about the constant escapement’s development.

Monochrome: What do you think of Girard-Perregaux’s Constant Escapement watch?

Déhon: It is beautiful. The first time that I saw it, the finished watch, it was very emotional for me.

Monochrome: Why?

Déhon: It took ten years for me. For me, the project started in 1997.

Monochrome: With Rolex. What was the name of that project?

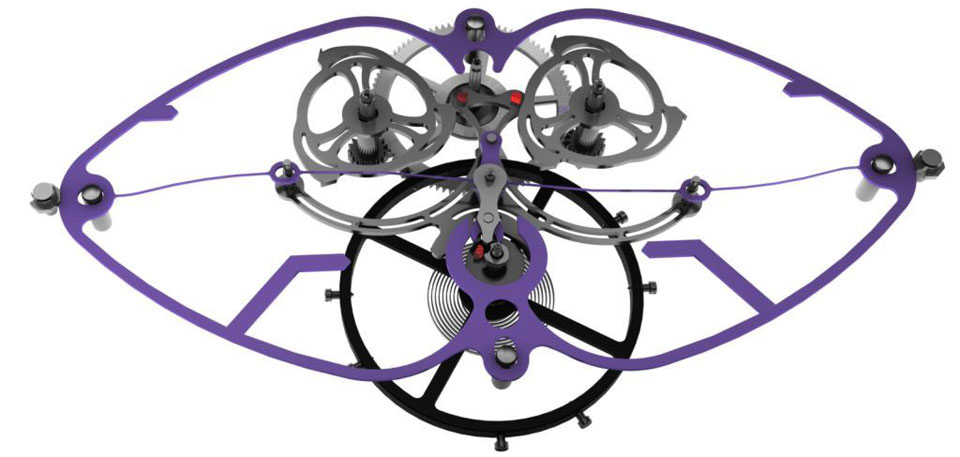

Déhon: Project E.L.F. (an abbreviation in French). E (Échappement) means escapement; L (Lame) in English means blade; and F (Flambage) means buckle in English. I think the project was completely different from any other escapement. It was not possible for Rolex to pursue the project. Rolex was the best of times. When I worked at Rolex, I had plenty of time to work on the project and concept. I think it would be impossible to start with this project’s concept under another manufacturer. Do you want to see the first prototype? It was like that. 20 Prototypes were made like that.

Monochrome: You didn’t have silicon, so what did you use for the blade?

Déhon: For the blade, it was Nivarox. None of these prototypes worked.

Monochrome: Why?

Déhon: The two points at the end [where the buckled-blade attaches to the spring frame] had to be perfectly collinear. If it wasn’t collinear, it would not work. Also, the blade and spring frame are now all one piece. That is the secret and why the prototype never worked at Rolex. Silicon was the needed technology for this concept.

Monochrome: So the Silicon blade is one factor that makes the escapement work, and the other factor is that the buckled-blade and spring frame are now all one piece.

Déhon: One piece [buckled-blade and spring frame together] is very important to achieve the precision at the two end points.

Monochrome: The Rolex ELF prototypes were the original. You went zero for twenty on the prototypes, but you didn’t lose faith?

Déhon: I felt the problem was here [inside my head]. When I came from Rolex to Girard-Perregaux, the silicon technology emerged. The project restarted at Girard-Perregaux in 2004. I arrived in 2002 and worked with them until 2008.

Monochrome: Did Girard-Perregaux know about the idea before you came?

Déhon: No. You can see the patent. The idea came to me on the train. I shared the idea when I saw the patent was down. Rolex stopped with the patent. I told Mr. Macaluso the patent was down; we can restart the project!

Monochrome: Tell me about [when the idea came to you on] train.

Déhon: It was a train ticket. Everyone can repeat the same experience by bending and unbending the ticket. It is a very special experiment everyone can make.

Monochrome: You started work on the constant escapement in 2004?

Déhon: I started in 2004 until 2008.

Monochrome: When you left, the project was unfinished?

Déhon: Yes. It was a prototype that you could see on the internet. It was a prototype that demonstrated the escapement, but the escapement worked. The concept, in my opinion, was finished in 2008.

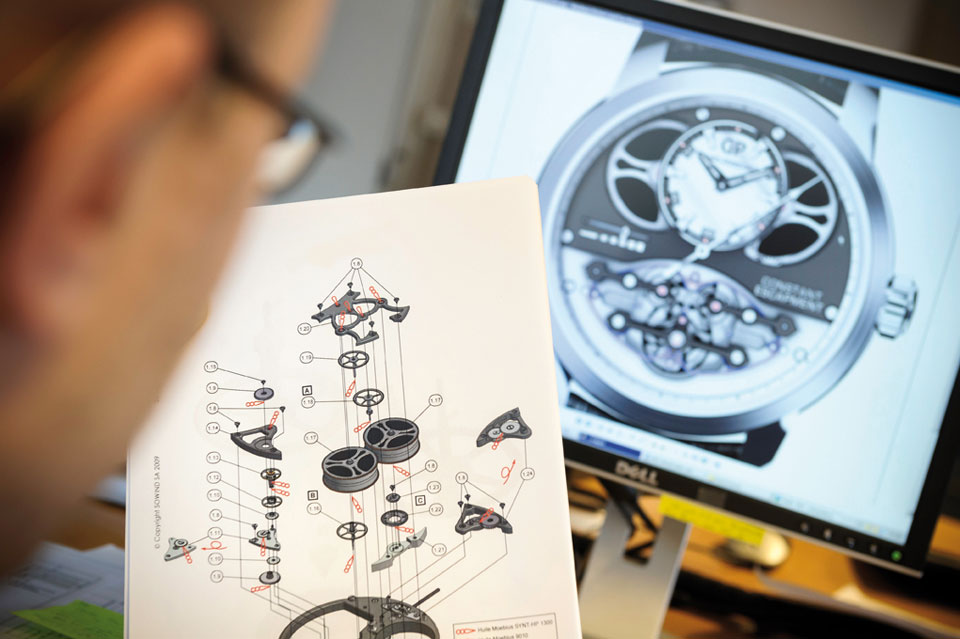

Monochrome: When you look at what you have in 2008 and the finished constant escapement now, did Girard-Perregaux develop it further?

Déhon: They improved the reliability of the escapement. In 2008, it would work only one or two days, and then stop. But the frequency was different; we worked with 4 Hz. Now it is 3 Hz. And the balance was quite different. The inertia was 12 milligrams centimeters squared, and now it is 8. The power is decreased, and the power reserve increased. I think it is a good choice. It took 5 years to redesign the 2008-version escapement with these new features and design an entirely new movement around it.

Monochrome: Your involvement in this design is important.

Déhon: The concept and the calculations of this escapement are my contribution to the final product presented this year, Stéphane Oes [engineer] and Laurent Calame [horologist] worked on the design of the complete movement and the optimization of the escapement at a new frequency [3 Hz]. In my opinion, despite these last improvements, we can work best with this escapement in the future. It is still not optimal now. We know the pallet escapement was invented by Thomas Mudge, and now almost 300 years later, we can see the pallet escapement, the Swiss escapement, everywhere. During this time, we must admit that this escapement was considerably improved. I don’t think we have to wait 200 years for this escapement to work perfectly. We have to wait maybe another ten years to get a constant escapement to work perfectly.

Monochrome: What is the accuracy of this escapement right now?

Déhon: Because the measurement devices that measure the rate of a watch are still not adapted to the new sound produced by the constant escapement, I have not heard anything about the accuracy, but the amplitude was very stable. For a period of 7 days, the Constant Escapement watch had the same amplitude plus or minus 3 degrees.

Monochrome: At the same time, we see others coming out with constant force escapements. These are very different than what we have here. How so? How is your device different than the others?

Déhon: In my opinion, the grand difference is the buckled-blade. It takes me 40 pages to describe exactly how it works. You can see the document. I left this with Girard-Perregaux.

Monochrome: Wow! The math! The equations!

Déhon: So, as you can see, this is the blade at first order and second order. All these graphics were done before building the concept. The blade works at 20mm. If you make it at 16mm, it doesn’t work without changing other parameters, so you have to be very accurate and have to calculate each parameter independently [length, thickness, total compression, E-modulus for the escapement and inertia amplitude, frequency, and quality factor for the oscillator].

Monochrome: A hundred years from now, when constant escapements are everywhere…

Déhon: No. This escapement is dedicated for “haute horlogerie.”

Monochrome: Well then, a hundred years from now, your name will be in the annals of horology.

Déhon: I really don’t know, but I don’t think I will have another project like that in my life. It was so interesting. I remember the first time that the prototype went tick-tick-tick; it was the second of February 2008. I remember it like it was yesterday.

We like to thank both Niclas Déhon and Girard-Perregaux for allowing us time for this interview. For more information about the Girard-Perregaux Constant Escapement L.M. watch, please visit their website here.